Add to Cart

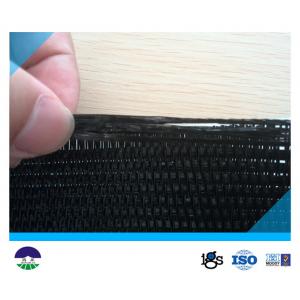

High Strength Woven Geotextile Corrosion Resistance

Description:

Monofilament Woven Geotextile MWG®, which incorporate round strands that are extruded. It is composed of hightenacity polypropylene yarns, which are woven into a network such that the yarns retain their relative position. Monofilament woven geotextile is preferred for applications where both strength and filtrationare a concern, such as shoreline rip rap applications.

Specification sheet:

| PROPERTIES |

| TEST METHOD | UNIT | NOMINAL VALUE |

| Tensile Strength | MD | ASTM D 4595 | kN/m | 52.5 |

| Tensile Strength | CD | ASTM D 4595 | kN/m | 47.3 |

| Elongation | MD | ASTM D 4595 | % | 25 |

| Elongation | CD | ASTM D 4595 | % | 25 |

| Tensile Strength at |

|

|

|

|

| 2% | MD | ASTM D 4595 | kN/m | / |

| 2% | CD | ASTM D 4595 | kN/m | / |

| 5% | MD | ASTM D 4595 | kN/m | 21.9 |

| 5% | CD | ASTM D 4595 | kN/m | 22.8 |

| Factory Seam Strength |

| ASTM D 4884 | kN/m | 42.0 |

| Apparent Opening Size |

| ASTM D 4751 | mm | 0.43 |

| Permittivity |

| ASTM D 4491 | sec-1 | 0.9 |

| Water Flow Rate |

| ASTM D 4491 | l/min/m2 | 1630 |

| UV Resistance (% retained after 500 hours) |

| ASTM D 4355 | % | 80 |

Filtration : By woven into a regular network and calendared , the filaments retain dimensional

stability relative to each other. These characteristics make it ideal for preventing the passage of

fine soil granules and allowing passage of fluid.

Reinforcement : Safely limit the excursion of civil work over long time of use and transfer or allocate

the stress on soil over a larger area

Separation : Separate the civil work materials into stable interfaces and ensure them to function both

individually and as a whole.

Cushion buffer : Placed on a slope , it can prevent soil granules from being flushed away

Corrosion resistance : The geotextile is resistant to ultraviolet degradation and also to biological

and chemical environments normally found in soils.